GENERAL SERVICES

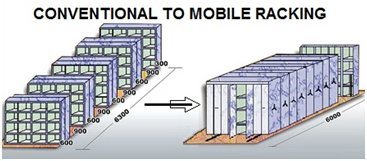

In the present economic scenario we appreciate that it is very much difficult for any business house to discard its existing conventional old storage systems and to go for a latest technical storage equipment. To help cut the financial cost of modernizing the storage system our skills have made it possible to convert your existing conventional racking systems into latest mobile storage systems by also consuming the material used in your existing system.

We undertake work contracts for shifting any and all kind of material storage systems inside or outside the industry . Our trained skilled experts assure minimum damage during dismantling, transit or re-installing the racking structure.

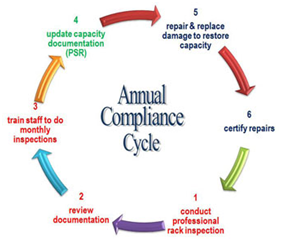

Let it be any racking storage system from static pallet racks to semi-automated or fully automated carousals ,we undertake all kind of repairs and reconditioning on very economical cost and that is also based on latest techniques without hurdling industry operations even if we have to provide standby structures.

We are the first enterprise to provide annual maintenance contracts for all kind of racking structure even if the rack product is being manufactured by any other party.

CONSULTATION SERVICES

If you are planning to establish new store / warehouse and you have the floor area then you need professionals to set your racking layouts. We provide services of designing complete rack layouts in your floor space with key consideration factors such as Maximum space utilization, Minimum inventory wastage ,Minimum retrieval time & Minimum human effort. Furthermore we also serve with comprehensive comparative report if you are planning to modernize your existing store to new one .

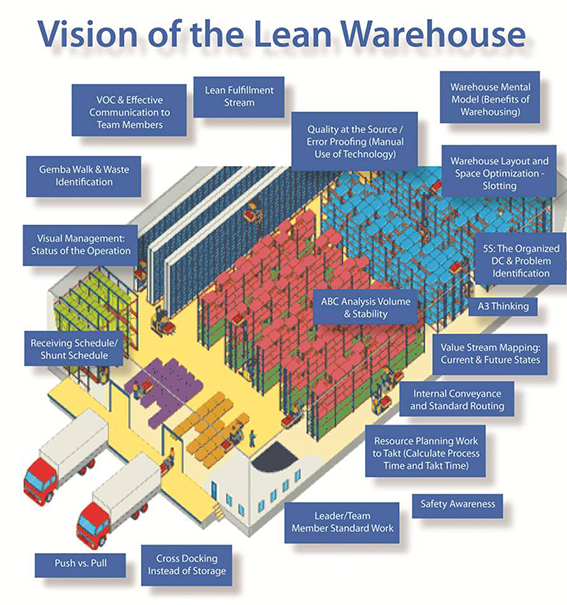

Today’s Warehouse Management Challenges make Lean six sigma philosophy an indispensable business strategy to survive, sustain and achieve high performance consistently. We, at NPME, see Warehouse operations from a value stream angle connecting all the elements of warehouse operations and eliminate non value adding activities to improve process velocity and to reduce operational cost for healthy bottom line benefits. NPME’s sole objective of implementing Lean Six Sigma is to increase the shareholder value of our partnering client organizations by improving KPIs such as improving cycle count accuracy, reducing packing discrepancy, reducing truck turnaround time, visual management systems to reduce stock retrieval time, optimizing truck loading and unloading time.

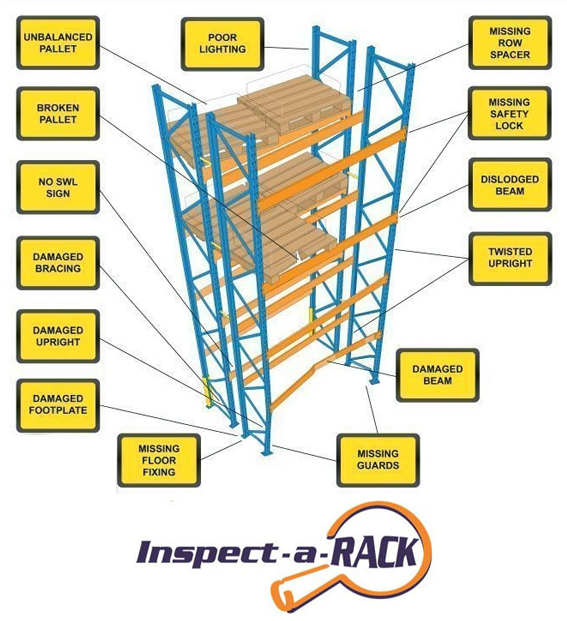

This service is a critical service as in industry due to busy schedules sometime it happens that small ignorance to faults leads to major disasters. Some faults are not even visual but when erupt ,then damages are huge. Our technical team assesses these faults to its minute level by doing product safety audit and thereby generating a complete report of all the minute issues let it be in small industrial stores or huge warehouses/ distribution centers.

Temporary to permanent warehouse leasing solutions ,is our provision weather anybody wish to lease his own warehouse space or vice versa i.e. if any body wants to have warehouse space on lease. Furthermore solution is so customized even to accommodate rent on unit basis i.e. per pallet or per box storage rental rates. Options are open & so flexible whether to go for per square feet( floor area) rates or go for per cubic feet rates.